About Maximum Load Of Price List Ball Mill

.jpg)

How To Calculate Ball Mill Load? Optimize Grinding

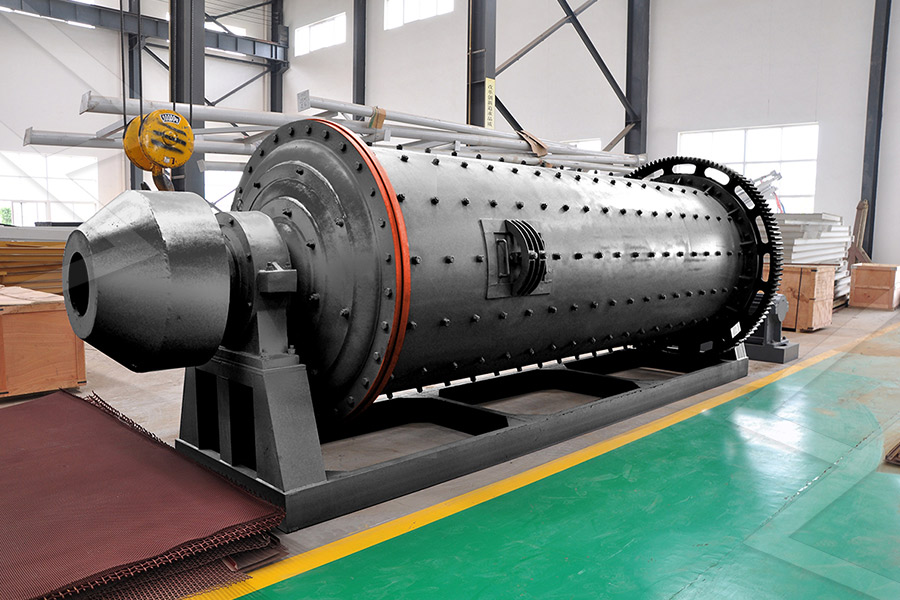

Optimal Load: Typically, the ball mill load should be around 4050% of the mill's total volume for efficient grinding Overloading: Excessive load can lead to inefficient grinding, increased power Laboratory drum ball mill is an ultrafine grinding and mixing equipment used in laboratories and small batch production This machine is beautiful and novel, has a compact structure, is easy TIANCHUANGFENMO QM15 Laboratory Roller Ball mill Maximum load 2015年6月19日 Use this online calculators for Motor Sizing and Mill sizing as well as mill capacity determinators In extracting from Nordberg Process Machinery Reference Manual I will also provide 2 Ball Mill Sizing (Design) Ball Mill Design/Power Calculation2024年10月12日 As a leading manufacturer in the industry, we take immense pride in offering our customers a wide range of laboratory ball mill specifications and price lists This article laboratory ball mill specification pricelist2025年4月25日 To determine the appropriate ball loading quantity, we need to choose the appropriate ball loading ratio Consideration factors include the size of steel ball, ball diameter series, the proportion of balls of various specifications How to choose the ball loading and loading 2024年10月13日 Ball mill specifications are an essential aspect of the mill's design and operation Understanding and optimizing key parameters such as chamber diameter and Ball mill specifications: A comprehensive guide

.jpg)

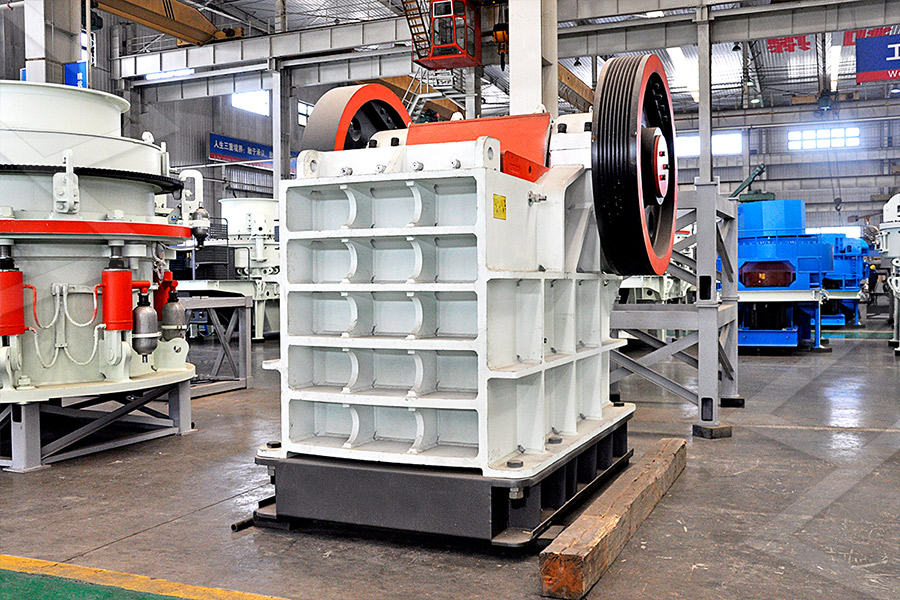

Ball Mill Zhengzhou Shibo Machinery

35 行 2024年8月14日 The Price List of Ball Mill different Models certainly will have the various price, and our company can promise for the 100% factory price and max discount for our customers in order to get the longterm cooperation2024年12月13日 Steel Ball Loading and Sizing in Ball Mills Steel Ball Loading Amount: The total ball loading varies depending on the ball mill model For example, the MQG1500×3000 ball mill (with a processing capacity of 100150 Ball Mill Loading Ratio and Steel Ball Size 2012年12月20日 Some modeling techniques, such as fast Fourier transform (FFT), mutual information (MI), kernel partial least square (KPLS), brand and band (BB), and adaptive Modeling Load Parameters of Ball Mill in Grinding Process 2021年5月1日 However, the ball mill has the disadvantages of low working efficiency and high energyconsumption To improve the grinding performance, the ball mill load must be tweaked A method to identify wet ball mill’s load based on 2024年7月9日 The Effect of Ball Load The efficiency of the ball mill heavily relies on the proper amount of grinding balls loaded into it Overloading the ball mill with too many balls results in overlapping, diminishing the grinding effect Different sizes of mill balls2024年5月27日 Ball mills are essential for grinding and pulverising ores in mineral processing Learn about their general function, design, and MechProTech's OEM offerings The TITAN design enables you to run a full Ball Mills in the Mineral Processing Industry

.jpg)

Understanding Ball Mills: Principles, Design, and Applications

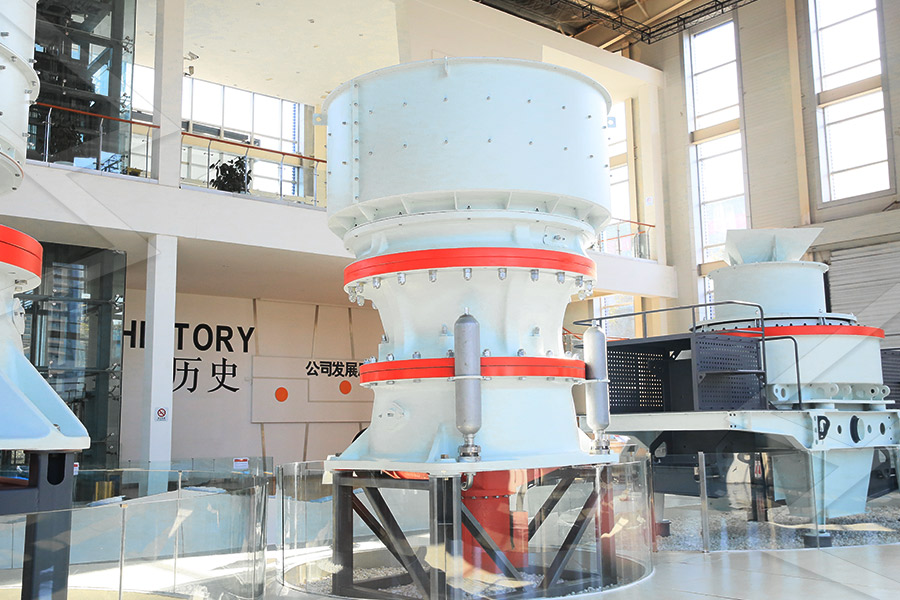

2025年3月1日 Grinding in ball mills is a crucial process used across various industries, including mining, metallurgy, cement production, and chemical manufacturing Ball Load and Size Tongli Heavy Machinery It was first established in 1958 After working hard for more than 65 years, Tongli has owned the firstclass science and technology development centers and ABOUTTongli Machinery ballmillsPrice Multi Frequency Ultrasonic Cleaner LMMU $30/pack of 1 Add without Accessories Add with Accessories +1 (301) 4500503; Ask An Expert; Home; Ball Mill 9 What is Critical Load Ball Mill Ball Mill Supplier Labmate2015年10月9日 Calculating a grinding circuit’s circulating loads based on Screen Analysis of its slurries Compared to %Solids or Density based Circulating load equations, a more precise Ball Mill Circulating Load Formula 911Metallurgist2024年8月14日 The Hotsale Models and Capacity of Ball Mill 900 × 1800, 1200 × 2400, 1500 × 3000, 1830 × 6400, 2200 × 9500 are the popular models our technical people often Ball Mill Zhengzhou Shibo Machinery Manufacturing Co, Ltd2017年2月13日 In all ore dressing and milling Operations, including flotation, cyanidation, gravity concentration, and amalgamation, the Working Principle is to crush and grind, often with rod Ball Mills 911Metallurgist

.jpg)

Ball Mills – efficient grinding FLS FLSmidth

Ball mills can be utilized as a primary grinding stage (after precrushing) or as a secondary grinding operation following a SAG mill Additionally ball mills are also implemented for regrind 2019年8月14日 Moreover, the price of ball mills is relatively expensive among many beneficiation equipment Therefore,after successfully purchasing a ball mill, it is necessary to The Ultimate Guide to Ball Mills Miningpedia2010年4月23日 Optimization of mill performance by using online ball and pulp measurements by B Clermont* and B de Haas* Synopsis Ball mills are usually the largest consumers of energy Optimization of mill performance by using SAIMM2017年9月18日 关键词: 迁移学习, 流形正则化, 最大均值差异, 湿式球磨机负荷参数, 集成, 过程控制, 预测 Abstract: Aiming at the challenging problems such as the measurement of key load 基于流形正则化域适应湿式球磨机负荷参数软测量 cip2022年4月21日 Soft measurement of ball mill load under variable working conditions based on deep transfer learning Peng Huang 2,1, Jiaming Guo 1, As shown in figure 2 and table 1, Soft measurement of ball mill load under variable working 2023年2月11日 be applied on ball mill operation using SSE as measured from a baseline, and other methods The JKSimMet® ball mill model is also not constrained from a volumetric and Digital Solutions to Evaluate Ball Mill Circuit

.jpg)

How to load balls in a ball mill? shanvim

How to load balls in a ball mill? The main function of the ball in the ball mill is to crush and grind minerals, so the proportion of balls in the ball mill is to meet the purpose of crushing and It enables operators to adjust various parameters such as mill speed, ball charge volume, or classification efficiency to achieve desired results By controlling and adjusting these how to calculate circulating load in ball mill – stone cruxderBall mill grinding machines are valuable tools in various industries, offering efficient and reliable grinding and mixing capabilities Understanding their working principle, different types, parts, Ball Mill Grinding Machines: Working Principle, Types, Parts 2018年10月19日 SCI (under normal load) = 73 kg\kg SCI (under tight load) = 1443 kg\kg The calculations clearly illustrate that the grinding balls mill load is twice efficient under the tight Increasing the load density of grinding balls in the mill2023年2月15日 High temperature of the ball mill will affact the efficiency 3 For every 1% increase in moisture, the output of the ball mill will be reduced by 8% 10% 4 when the 17 Signs of Problems with Ball Mills: Quickly Remove Hidden Troubles2024年11月15日 Ball mill for cement grinding Cement grinding is a crucial stage of the flow sheet, where both cement quality and process efficiency are decided Achieving the required BALL MILL FLSmidth Cement

.jpg)

How To Calculate Ball Mill Load? Optimize Grinding

Components of Ball Mill Load: Grinding Media (Balls): The steel or other material balls used for grinding Their volume and density are critical for load calculation Ore: The material to be 2025年4月28日 Ball mills are scalable to large, continuous units that can process large volumes, and are therefore well suited to this use 2 Ceramics Ceramics manufacturing uses mixtures Ball Mills: Types and Uses ThomasnetThe Magotteaux ball loading machine enables to load the grinding media into a tube mill in a very fast (1525 tph) and safe way side can be adjusted in all directions ie up/down and Ball loader Magotteaux2023年12月12日 The main way to improve the performance of ball mills is to optimize the operating modes of the electric drive and mill equipment, to ensure stable operation of the ball (PDF) Control of ball mill operation depending on ball load 2024年10月23日 Feeding the Mill: Load the material into the ball mills through the inlet It’s essential to adhere to the maximum fill level to prevent overflow and maintain optimal grinding News lanemachineryThe circulating load ratio is known to be an extremely important design/operating parameter, as shown in Figure 2 Figure 1 Standard Ball Mill Circuit Arrangement Figure 2 Ball Mill Circuit Grinding Bulletin #1 – Metcom Technologies

.jpg)

Ball Mills Suitable for every application Retsch

Retsch visualises the features and strengths of each ball bill model in a diagram to help finding the right model for a specific application In the example shown it is easy to see that the 5 天之前 Ball mills grind various ores and other materials either wet or dry There are two kinds of ball mills, grate type and overflow type, due to different ways of discharging material There New and Used Ball Mills for Sale Ball Mill Supplier Worldwide2024年9月24日 Investigations were carried out in a laboratory ball mill having the size of DxL = 160x200 mm with a ribbed inside surface of the drum The mill ball loading was 40% by THE OPTIMAL BALL DIAMETER IN A MILL 911 2021年5月1日 However, the ball mill has the disadvantages of low working efficiency and high energyconsumption To improve the grinding performance, the ball mill load must be tweaked A method to identify wet ball mill’s load based on 2024年7月9日 The Effect of Ball Load The efficiency of the ball mill heavily relies on the proper amount of grinding balls loaded into it Overloading the ball mill with too many balls results in overlapping, diminishing the grinding effect Different sizes of mill balls2024年5月27日 Ball mills are essential for grinding and pulverising ores in mineral processing Learn about their general function, design, and MechProTech's OEM offerings The TITAN design enables you to run a full Ball Mills in the Mineral Processing Industry

Understanding Ball Mills: Principles, Design, and Applications

2025年3月1日 Grinding in ball mills is a crucial process used across various industries, including mining, metallurgy, cement production, and chemical manufacturing Ball Load and Size Tongli Heavy Machinery It was first established in 1958 After working hard for more than 65 years, Tongli has owned the firstclass science and technology development centers and ABOUTTongli Machinery ballmillsPrice Multi Frequency Ultrasonic Cleaner LMMU $30/pack of 1 Add without Accessories Add with Accessories +1 (301) 4500503; Ask An Expert; Home; Ball Mill 9 What is Critical Load Ball Mill Ball Mill Supplier Labmate2015年10月9日 Calculating a grinding circuit’s circulating loads based on Screen Analysis of its slurries Compared to %Solids or Density based Circulating load equations, a more precise Ball Mill Circulating Load Formula 911Metallurgist2024年8月14日 The Hotsale Models and Capacity of Ball Mill 900 × 1800, 1200 × 2400, 1500 × 3000, 1830 × 6400, 2200 × 9500 are the popular models our technical people often Ball Mill Zhengzhou Shibo Machinery Manufacturing Co, Ltd2017年2月13日 In all ore dressing and milling Operations, including flotation, cyanidation, gravity concentration, and amalgamation, the Working Principle is to crush and grind, often with rod Ball Mills 911Metallurgist

.jpg)

Ball Mills – efficient grinding FLS FLSmidth

Ball mills can be utilized as a primary grinding stage (after precrushing) or as a secondary grinding operation following a SAG mill Additionally ball mills are also implemented for regrind Optimal Load: Typically, the ball mill load should be around 4050% of the mill's total volume for efficient grinding Overloading: Excessive load can lead to inefficient grinding, increased power How To Calculate Ball Mill Load? Optimize Grinding Laboratory drum ball mill is an ultrafine grinding and mixing equipment used in laboratories and small batch production This machine is beautiful and novel, has a compact structure, is easy TIANCHUANGFENMO QM15 Laboratory Roller Ball mill Maximum load 2015年6月19日 Use this online calculators for Motor Sizing and Mill sizing as well as mill capacity determinators In extracting from Nordberg Process Machinery Reference Manual I will also provide 2 Ball Mill Sizing (Design) Ball Mill Design/Power Calculation2024年10月12日 As a leading manufacturer in the industry, we take immense pride in offering our customers a wide range of laboratory ball mill specifications and price lists This article laboratory ball mill specification pricelist2025年4月25日 To determine the appropriate ball loading quantity, we need to choose the appropriate ball loading ratio Consideration factors include the size of steel ball, ball diameter series, the proportion of balls of various specifications How to choose the ball loading and loading

.jpg)

Ball mill specifications: A comprehensive guide

2024年10月13日 Ball mill specifications are an essential aspect of the mill's design and operation Understanding and optimizing key parameters such as chamber diameter and 35 行 2024年8月14日 The Price List of Ball Mill different Models certainly will have the various price, and our company can promise for the 100% factory price and max discount for our customers in order to get the longterm cooperationBall Mill Zhengzhou Shibo Machinery 2024年12月13日 Steel Ball Loading and Sizing in Ball Mills Steel Ball Loading Amount: The total ball loading varies depending on the ball mill model For example, the MQG1500×3000 ball mill (with a processing capacity of 100150 Ball Mill Loading Ratio and Steel Ball Size 2012年12月20日 Some modeling techniques, such as fast Fourier transform (FFT), mutual information (MI), kernel partial least square (KPLS), brand and band (BB), and adaptive Modeling Load Parameters of Ball Mill in Grinding Process